Investing in Space: What Risks Lie in the Final Frontier

Explore the main risks of investing in space ventures and why understanding them matters for success.

Introduction

The commercial space industry is undergoing a period of rapid and innovative transformation. What was once the exclusive domain of government agencies, such as NASA, is now a growing area for private companies, ranging from multinational aerospace firms to fully new startups. Satellites are becoming indispensable for Earth observation, telecommunications, and global connectivity. In-orbit manufacturing offers the possibility of producing advanced materials and pharmaceuticals that cannot be replicated here on Earth. Meanwhile, new projects in space tourism seek to make human spaceflight a commercial enterprise rather than a scientific endeavor alone. These opportunities are reshaping how investors view the final frontier, not merely as an exploration challenge, but as a potential engine for growth and high returns on investment.

Unlike traditional industries, space ventures are shaped by extreme physical environments and unforgiving operational constraints. A single failed launch, unexpected exposure to radiation, or flaw in adapting technology to microgravity can result in high amounts of financial loss. For this reason, investors and operators need to approach the space sector with a clear understanding of its unique challenges. Recognizing these risks is not intended to discourage participation, but rather to enable informed decision-making and the development of strategies that anticipate both setbacks and new opportunities.

By understanding the risks of space ventures, stakeholders can better navigate challenges and lower the chance of losses.

Launch Risk

The journey to space begins with launch, and this stage represents one of the most significant risks to both technology and investment. Rockets are among the most complicated machines ever designed, containing thousands of individual parts that must operate flawlessly under intense thermal, acoustic, and mechanical stressors. Even minor malfunctions can result in mission failure, destroying payloads worth hundreds of millions of dollars in a matter of seconds.

While launch technology has improved significantly over the past two decades, the risk of failure is still higher than in many other industries — yet the potential rewards from breakthroughs, market expansion, and first-mover advantage continue to attract stakeholders across the space ecosystem.

To mitigate these risks, companies subject payloads to exhaustive pre-launch testing. Vibration chambers replicate the violent shaking of rocket ascent, acoustic facilities blast payloads with high-decibel noise to mimic liftoff conditions, and centrifuge testing reproduces the G-forces experienced during launch. Despite these precautions, the inherent uncertainty of rocket flight cannot be fully eliminated. For instance, if a satellite constellation operator loses one spacecraft during launch, the setback can cascade: replacement costs increase, deployment schedules slip, and competitors may seize market share. This can translate into delayed revenue, disrupted business models, and a potential loss of confidence in both the company and the broader sector as a whole.

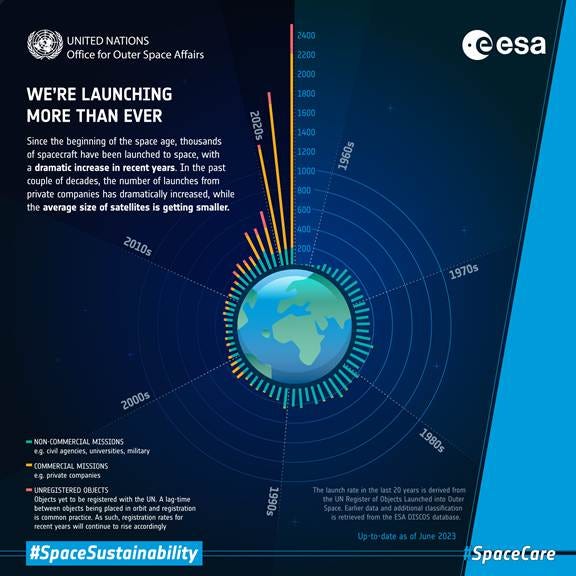

In addition to these inherent technical risks, the growing number of global launches increases operational complexity. More missions in orbit mean greater traffic and potential challenges in managing congestion, which can impact operators and, in some cases, the broader market. But this also creates more opportunities for market expansion, collaboration, and innovation in orbital services.

Radiation

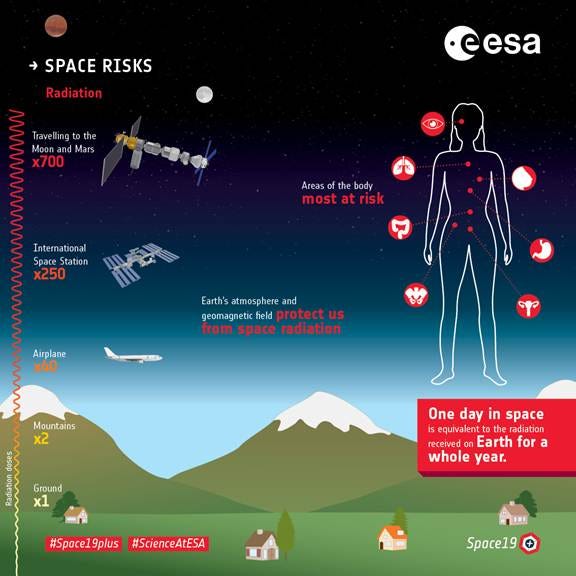

Once a payload reaches orbit, it enters an environment where radiation is a constant and invisible hazard. Unlike on Earth, where the magnetic field and atmosphere shield us from harmful cosmic rays and solar storms, satellites and spacecraft in orbit are exposed to a continuous stream of energetic particles. This radiation gradually degrades solar panels, interferes with onboard electronics, and can cause sudden failures in even the most robust systems. For human spaceflight missions, radiation presents notable health concerns, ranging from a higher likelihood of long-term effects like cancer to shorter-term risks during solar events.

Radiation remains a persistent risk in orbit, requiring careful mitigation. Advances in shielding can protect missions and enable innovations like safer cancer therapies, high-altitude aviation protection, and more resilient electronics.

Mitigation strategies are complex and expensive. Engineers design radiation-hardened components capable of withstanding higher doses of radiation, integrate shielding materials where weight allows, and employ redundancy so that if one system fails, another can assume its function. Extensive ground-based testing in simulated radiation environments provides valuable data but cannot perfectly replicate the conditions of deep space. These factors that complicate financial projections and make it essential to treat radiation as a core environmental variable, not an incidental challenge. At the same time, tackling radiation is not just a cost center but a potential catalyst for major breakthroughs. Advances in shielding technologies could reshape the economics of spaceflight while also creating spillover benefits on Earth, from safer cancer treatments to improved protection in aviation and nuclear energy.

Microgravity and Altered Physics

Perhaps the most subtle but equally consequential challenge of space is the altered physical environment beyond Earth’s atmosphere. In microgravity, the absence of weight changes how matter behaves in ways that affect both engineering systems and biological organisms. Fluids do not settle or flow as expected, leading to complications in fuel storage and delivery systems. Heat does not dissipate through convection, forcing spacecraft designers to develop specialized cooling solutions for electronics and materials. Even structural components may respond differently under conditions of continuous freefall, creating new engineering puzzles.

Human physiology is also profoundly affected. Astronauts in orbit experience muscle atrophy, bone density loss, and changes to cardiovascular function after prolonged exposure to weightlessness. For companies pursuing space tourism or long-duration missions, these physiological risks introduce new costs in terms of training, medical monitoring, and life support systems. On the other hand, microgravity also creates opportunities. Manufacturing in orbit can produce materials with properties unattainable on Earth, such as ultra-pure crystals or novel pharmaceuticals. Yet capitalizing on these advantages requires overcoming significant engineering and biological challenges first.

The altered physics of microgravity highlights the need for careful evaluation. Technologies that function reliably on Earth cannot be assumed to perform the same way in space. Additional research, development, and adaptation are nearly always required, which can extend timelines, increase upfront costs, and add uncertainty to financial models. Failing to account for these factors may lead to underestimating both the risks and the capital needed to bring space-based innovations to market.

The altered physics of microgravity poses engineering and biological challenges, increasing costs and risks. Yet overcoming them can unlock major benefits, from medical insights into bone and muscle health to new manufacturing opportunities for advanced materials and pharmaceuticals.

Orbital Mechanics and Collision Risk

Operating in orbit requires navigating a crowded and dynamic environment. Thousands of satellites spent rocket stages and fragments of debris are already circling Earth at speeds exceeding 25,000 kilometers per hour. Even an object as small as a paint chip can cause catastrophic damage when traveling at orbital velocity. For operators, this creates the dual challenge of deploying satellites into useful orbital slots while avoiding collisions with both active spacecraft and debris.

Collision avoidance is therefore a constant operational task. Companies must track potential conjunctions, adjust orbits to reduce risk, and plan deorbit strategies for spacecraft at the end of their lifetimes. Each maneuver consumes fuel, shortens mission duration, and introduces operational complexity. Insurance can transfer part of this risk, but premiums rise with congestion, adding to ongoing costs.

Operating in orbit involves constant collision risks that must be managed through careful planning, adding complexity, cost, and potential operational disruptions, while also driving advanced innovations in satellite design, autonomous maneuvering, and space traffic management.

The European Space Agency (ESA) estimates its satellites carry out an average of three to four collision avoidance maneuvers per year. Each maneuver represents more than just a course correction: it consumes fuel, requires significant monitoring and planning time, and often interrupts data collection.

Thermal Extremes and Vacuum

Space is an environment defined by extremes. Temperatures swing from searing heat in direct sunlight to frigid cold in shadow, often within minutes as spacecraft orbit the Earth. At the same time, the vacuum of space removes the insulating and protective effects of an atmosphere. These conditions stress every component of a spacecraft, from solar arrays and sensors to lubricants and structural materials. Metals expand and contract, electronic systems can overheat or freeze, and conventional fluids evaporate in a vacuum, creating engineering challenges unlike any found on Earth.

Mitigating these risks requires advanced thermal management systems, specialized coatings, and redundant design to ensure performance under fluctuating conditions. Each of these solutions adds weight, complexity, and cost. As a result, thermal and vacuum challenges represent not just technical hurdles but also a source of financial uncertainty. Programs may require longer development cycles and higher capital expenditures to ensure reliability. These risks emphasize the importance of companies with proven engineering teams and demonstrated hardware resilience.

On the other hand, extreme space conditions have driven innovations in materials, coatings, and thermal systems. High-performance composites, heat pipes, and vacuum-rated lubricants developed for spacecraft now benefit aerospace, electronics, medical devices, and industrial machinery on Earth.

Extreme temperatures and the vacuum of space create unique engineering challenges that must be addressed through careful design, adding complexity, weight, and cost to spacecraft programs, while also driving innovations in materials, coatings, and thermal systems that now benefit aerospace, electronics, medical devices, and industrial machinery on Earth.

Why These Risks Matter

While the risks of launch, radiation, microgravity, collisions, and environmental extremes may appear purely technical, their consequences ultimately manifest in business outcomes. A failed satellite launch can disrupt a company’s business model. A premature component failure may cut mission lifespans in half, derailing financial projections. Prolonged R&D timelines to solve physics and engineering challenges extend burn rates and delay returns on capital.

Technical risks in space - like launch failures, radiation, and microgravity - directly affect business outcomes, making robust risk management and resilient systems just as important as market opportunity.

Companies that build redundancy into their systems, adopt thorough testing protocols, and maintain strong partnerships with insurers, launch providers, and technology partners are better positioned to succeed. Understanding how a team approaches these risks is just as critical as evaluating its market potential, since the balance between innovation and resilience often determines long-term viability.

The key is not to avoid these risks, but to understand them. By recognizing how technical challenges affect costs, timelines, and competitive positioning, stakeholders can identify ventures that are prepared to navigate the realities of space. Space remains a high-risk, high-reward sector, but informed decision-making enables participation in its growth while minimizing exposure to the hazards of operating beyond Earth’s atmosphere.

With millions of intricate parts working in perfect unison at takeoff, I still shudder at the enormity of the engineering feat every time I board a plane. Space travel by comparison feels nothing short of miraculous.